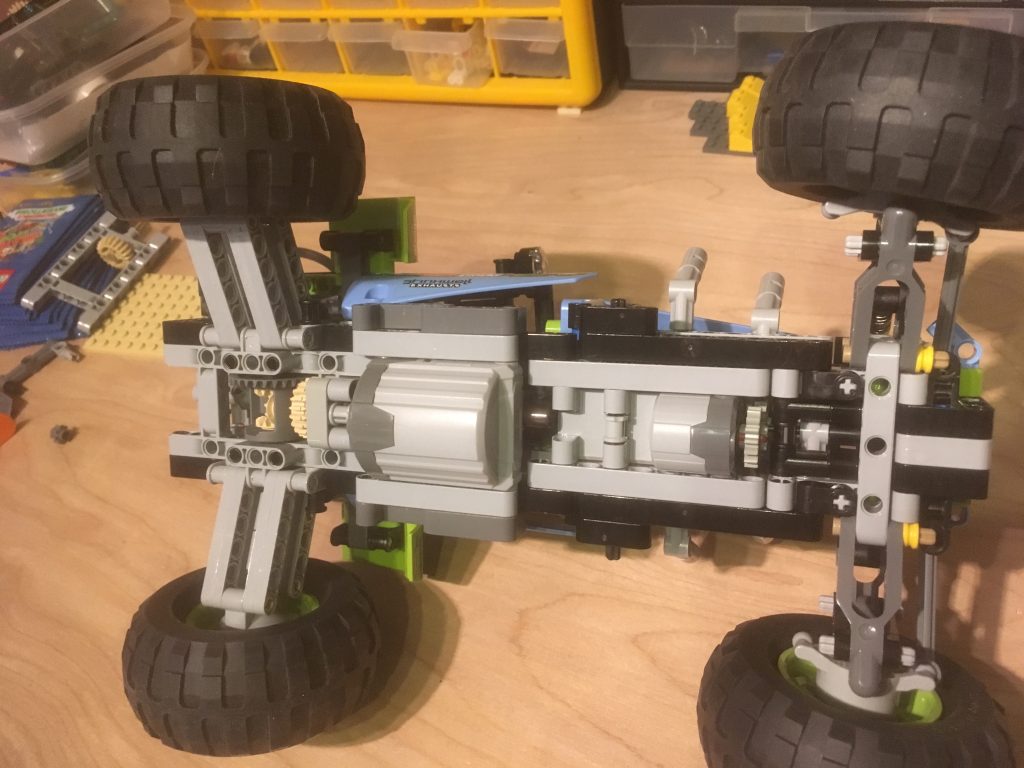

In my quest to build a reasonable remote controlled car in LEGO Technic, I tried rebuilding the 2015 off road set 42037. There is space to fit an L-Motor and a servo in the chassis (at the expense of the pistons mechanism for the engine). The battery box fits in the back of the roll-cage, and the IR receiver sits in the driver’s seat.

From a space perspective, this seemed a promising start. The motor shaft has an 8-tooth gear which drives another 8-tooth gear on the differential shaft. I tried various options for holding the drive shaft firmly in place so the gears wouldn’t cog.

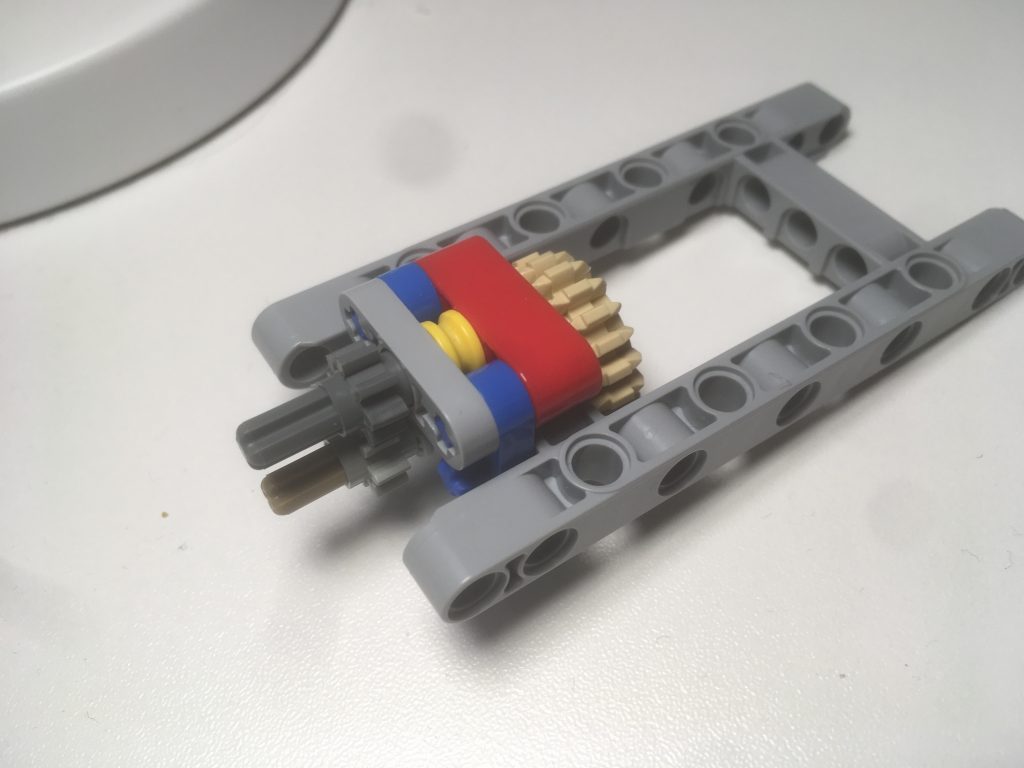

This option is sturdy enough that the motor shaft remains in place. In the car, I used 2L and 3L technic liftarms. A stronger connection can be made using 2L (shown in blue) and 3L (shown in grey) thin lift-arms which have cross-holes for a blue pin-axle.

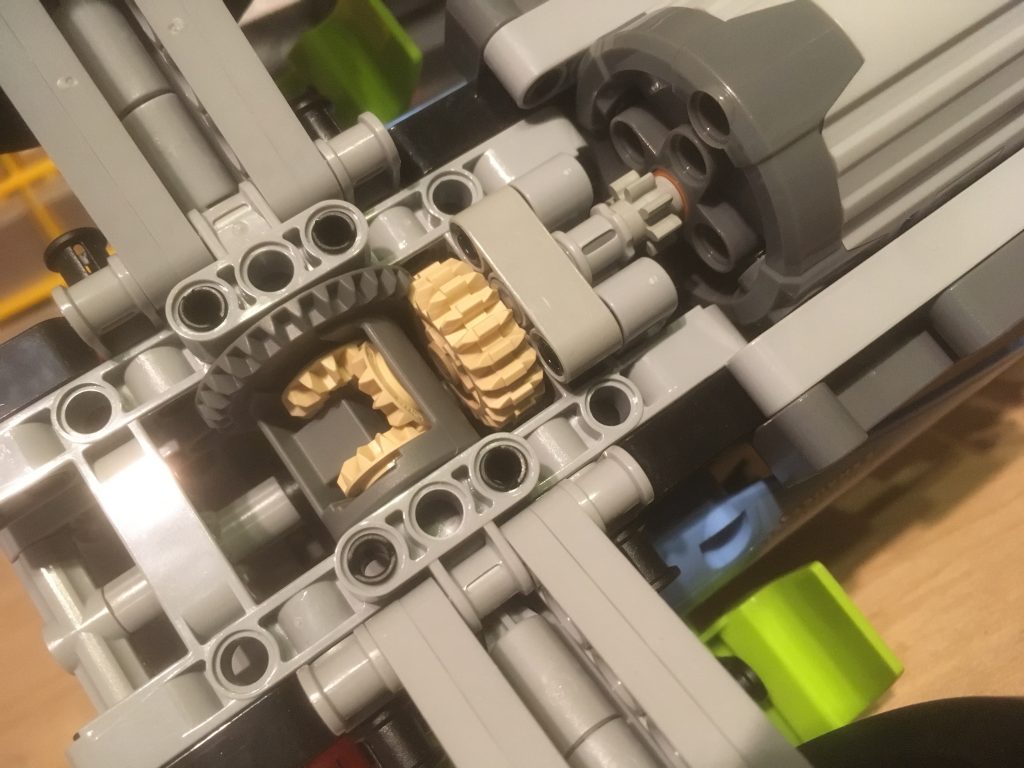

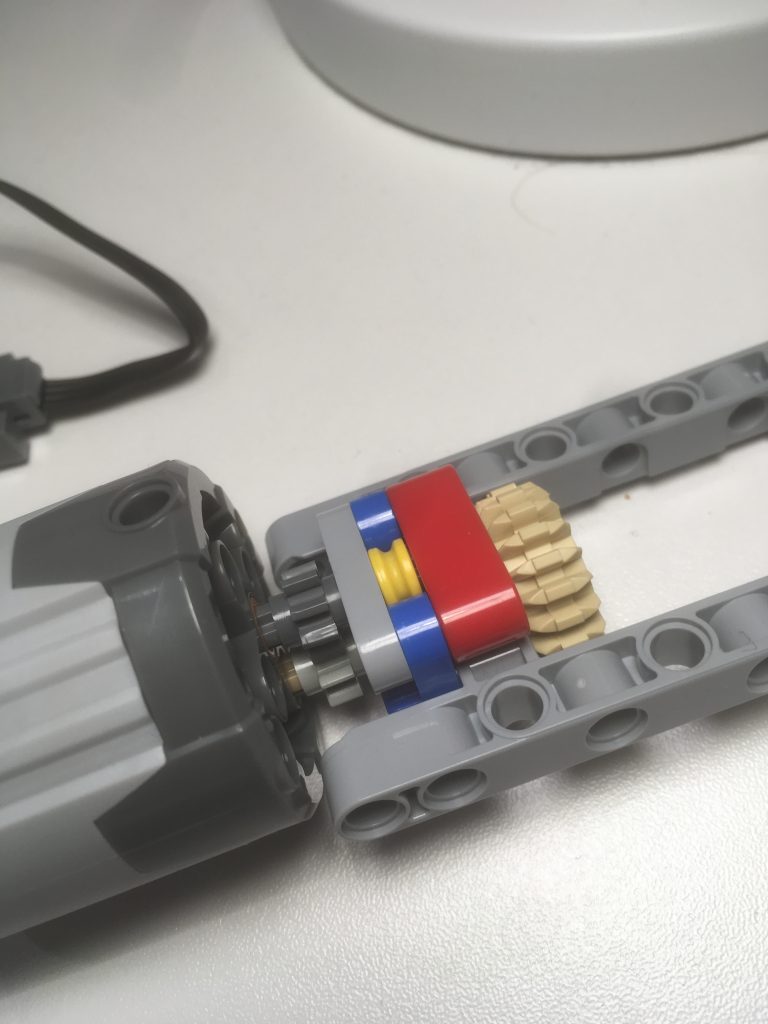

In the above picture, the dark grey 8-tooth gear is on the motor shaft. (with the yellow half-bush). The light-grey 8-tooth gear is on the tan crown gear that meshes with the differential.

Unfortunately, after a few minutes of play, the L-motor is powerful enough to cause damage to an 8-tooth gear: the teeth are forces sideways (in an anti-clockwise direction in the photo below).

Unfortunately there isn’t space to move the L-motor up vertically without seriously changing the structure of the car. Back to the workbench.